Today, Wuxi RIHUAN Sensing Technology Co., Ltd. will introduce to you a series of RIhuan's sensing ultrasonic sensors, which are suitable for all industrial scenarios.

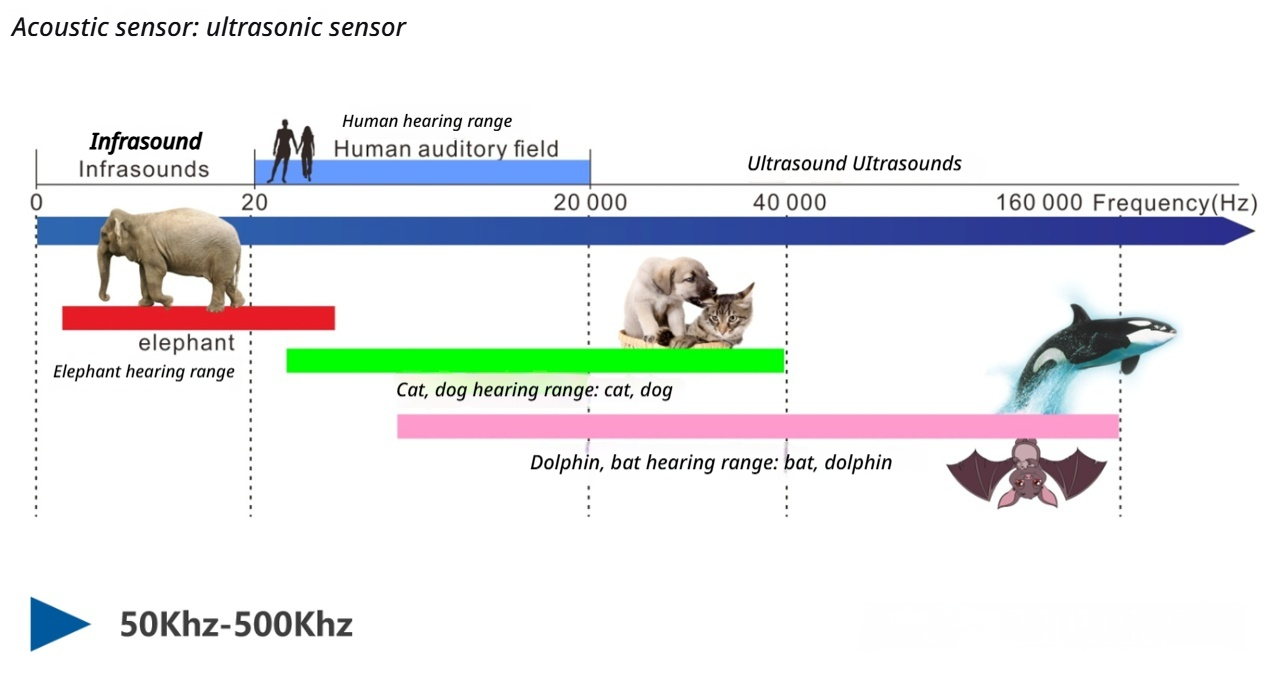

An ultrasonic sensor is a high-precision sensing device that converts ultrasonic signals into electrical signals. Ultrasonic waves are mechanical waves with frequencies higher than 20kHz, exceeding the audible range of the human ear. They possess excellent directionality, penetrating power and environmental adaptability. Thanks to these physical properties, ultrasonic sensors are widely used in multiple fields such as industrial automation, liquid level monitoring, biomedicine, and national defense security, playing an irreplaceable role.

The core characteristics of ultrasonic waves

- High frequency and short wavelength: More precise target detection can be achieved;

- Strong directionality: Weak diffraction effect, more stable propagation, and precise positioning can be achieved;

- Strong penetration: Suitable for detecting the internal structure of opaque solids and liquid media;

- Supports reflection and Doppler effect analysis: Can identify the target distance, shape, movement speed and direction.

Ultrasonic sensors calculate the distance or position of the target by emitting ultrasonic waves and receiving their echoes, and measuring the time difference from emission to reception. Its non-contact detection method is not affected by environmental light or the surface characteristics of objects, and it features high stability and accuracy.

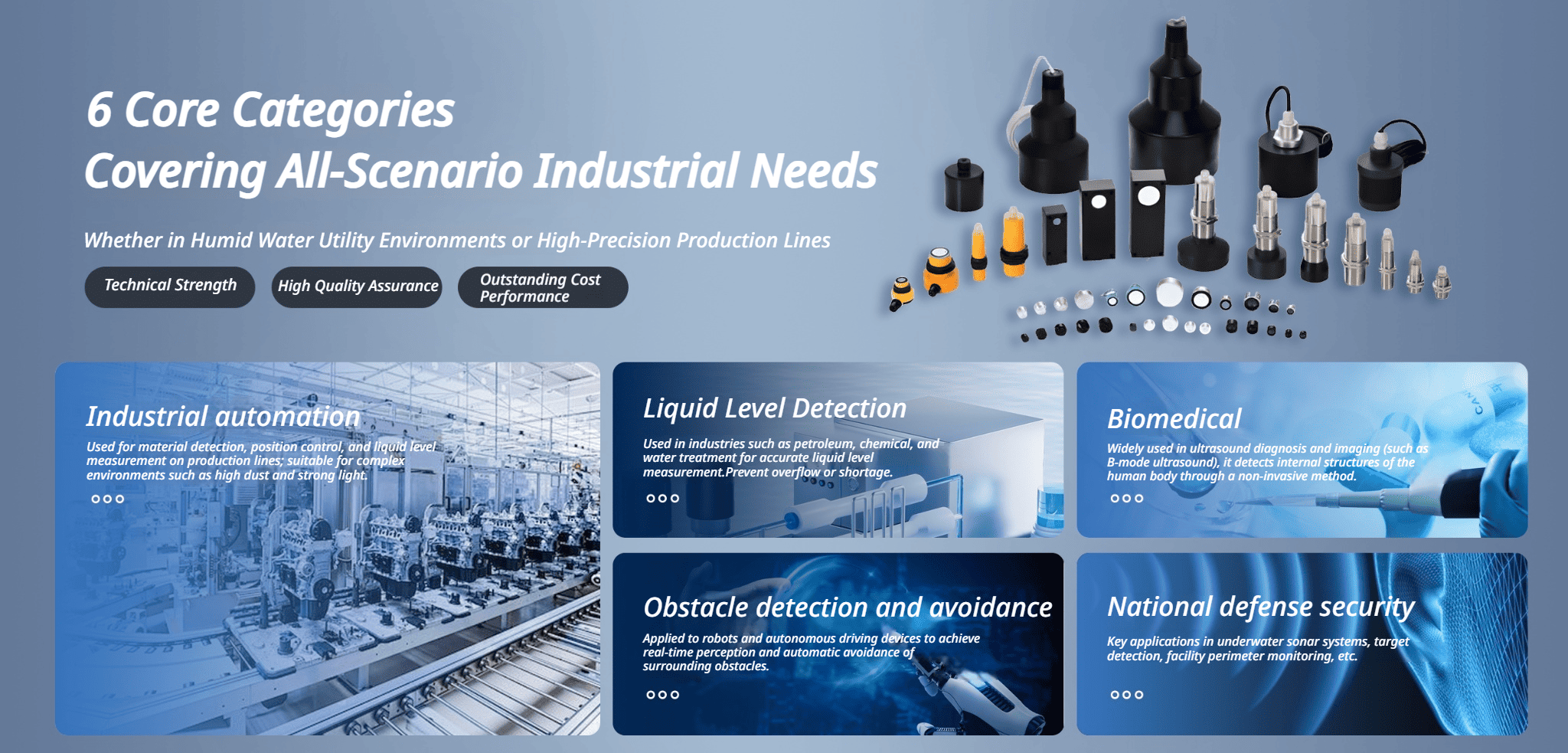

Six core categories, covering all industrial demands in various scenarios

Whether it is a damp water environment or a high-precision production line, Rihuan Sensing can provide suitable ultrasonic sensor products. Six core product categories, each of which has been refined through years of technological accumulation, precisely addressing industrial pain points

1. Open ultrasonic sensor: Flexible adaptation, easy transmission and reception

It adopts a separate or integrated transceiver design to adapt to different installation scenarios. Take the RH40C16TR-1 as an example. With a center frequency of 40Khz and a high transmission sensitivity of 117dB, a resolution of 10mm and a 60° directional Angle, it is available in both aluminum and plastic shells, easily meeting the demands of label inspection, obstacle detection, etc. It can be called a "precise judge" in packaging and printing production lines.

2. Waterproof ultrasonic sensor: Fearless of moisture, stable and reliable

With the IP protection structure, it can operate stably even in damp environments such as water tanks and sewers. The RH40A18TR-2 adopts an aluminum shell electroplating process, achieving a resolution of 10mm at a frequency of 40Khz and a wide directional Angle of 100°. It is equipped with anti-reverse connection and overvoltage protection circuits, making it a "powerful assistant" for smart water management and liquid level control.

3. High-frequency ultrasonic sensor: Millimeter-level accuracy, no detail overlooked

For high-precision detection scenarios, high-frequency sensors can be regarded as "detail-oriented". For instance, the RH200E15TR-2200 Khz high-frequency design, with a detection range of 0.05 to 1.5 meters, a resolution of 1mm and a narrow direction Angle of + 10°, performs exceptionally well in electronic component inspection and micro-distance measurement, achieving a repeatability accuracy of 0.1%, comparable to imported products.

4. Wind speed ultrasonic sensor: Meteorological grade monitoring, with precise data

Integrated high-performance piezoelectric ceramic transducers, taking RH200E12TR-1 as an example, with a frequency of 200Khz and a high input voltage of 500Vp-p, a resolution of 1mm and a 10° direction Angle, can achieve wind speed monitoring from 0 to 40m/s and wind direction monitoring from 0 to 360°. It is applicable to meteorological stations, agricultural research, aerospace and other fields, with a measurement accuracy of ±(0.3m/s+3% of the measured value).

5. Modular ultrasonic sensor: Multiple output options are available, and integration is convenient

Tailored for industrial system integration, it supports switch quantity/analog quantity/digital quantity/pulse output. The RH200F18GM series has a measurement range of 50-1000mm, a blind zone of ≤50mm, and is compatible with standard detection plates of 300*300mm. It has a repeatability accuracy of 0.3% and can be easily integrated into automated systems such as liquid level control and roll diameter detection, significantly reducing integration costs.

6. Dual-sheet detection sensor: Error-proof expert, efficiency doubled

For the problem of misdelivery of double or multiple sheets in the printing and packaging industries, the double-sheet detection sensor can be regarded as a "error-proof guardian". The RH200DC18GM series adopts an M18 installation size, is powered by a wide voltage range of 10-30V, and has a detection distance of 30-60mm. It can identify materials such as paper, plastic sheets, and aluminum foil paper with a thickness of ≤1.5mm. The response time is only 15ms. It is equipped with NPN/PNP output, effectively avoiding production waste.